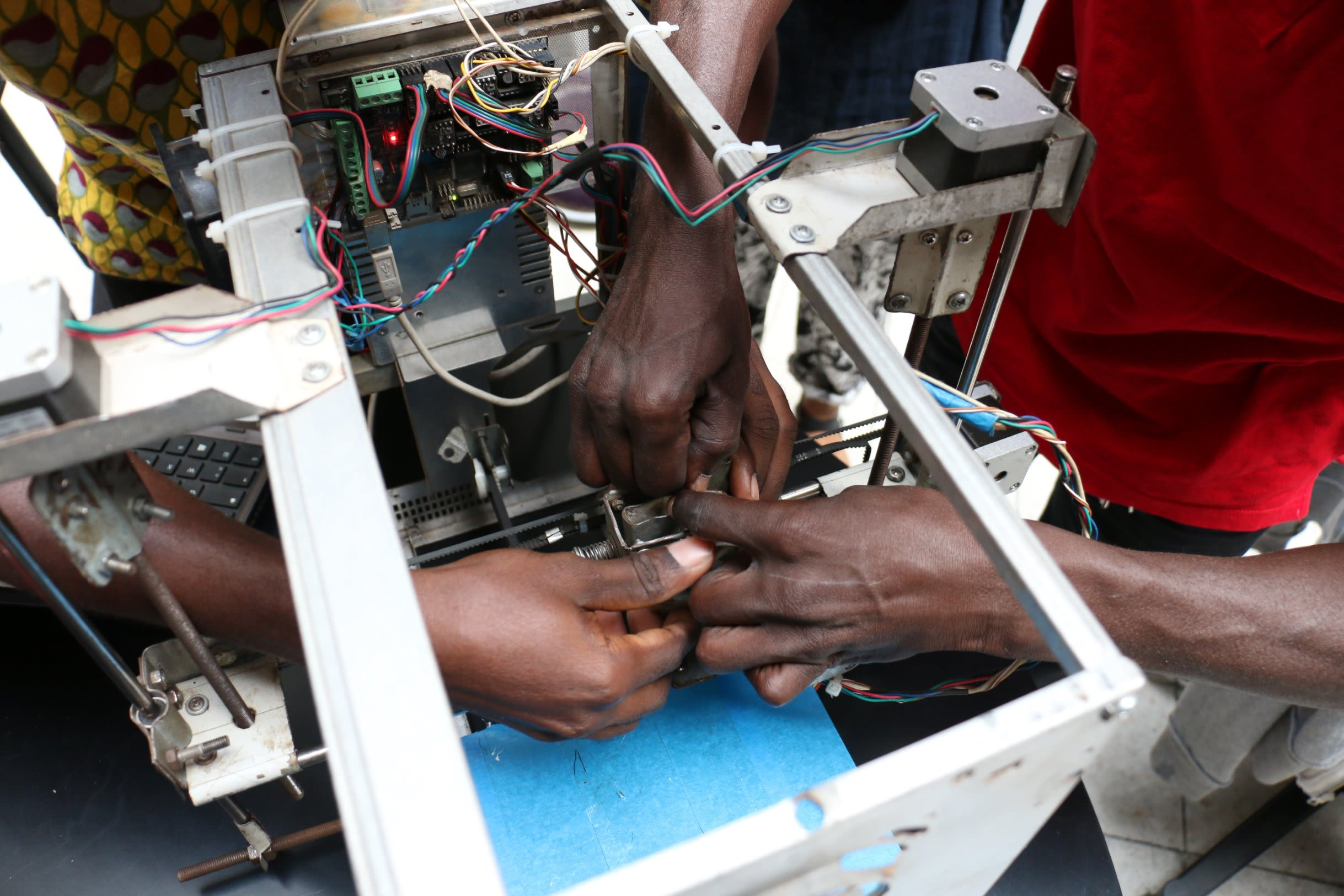

Students using a 3D printer in class, several views of Gonzaga instructing the students, Gonzaga demonstrating how a 3D printer works, and students paying close attention to Gonzaga

These kids are learning to relate their imaginative creations to three-dimensional things like toys, building blueprints, or medical equipment.

Even though their knowledge of 3D printing is still limited, it will soon revolutionize the manufacturing industry.

They are receiving time-consuming instruction from engineer Gonzaga Ntege so they can close the knowledge gap.

If you have a 3D printer, you can make something for your child or a relative instead of buying it. Joshua Nteza, a student remarked.

Ntege has constructed a 3D printing factory out of electronic waste back at the Zopah workshop.

Old photocopier and printer motors and rods have become valuable at this junkyard in downtown Kampala. Each is included as a crucial part of a 3D printing machine rather than being discarded.

In the next ten years, we want to reach as many African children as possible with this technology, so that when they are 15, 18, they will be asking, “Okay, how can we modify it, how can we change it?” Mechanical engineer at Gonzaga said.

“You find that a lot of photocopiers are being thrown out because they are getting stale. I’ve been buying motors almost every day for the past year, and I believe I now have about 1,000 motors. I currently have enough materials to build 100 printers. In order to create the necessary technology, we are attempting to utilize everything in this area. mechanical engineer/founder of gonzaga ntege said.

The project is already addressing issues with conventional plastic manufacturing techniques, which call for a sizable initial capital investment.

A machine can cost $50,000, and a mold can cost up to $6,000.

The process becomes 40% less expensive by utilizing local resources.

Their aims include encouraging upcycling, expanding access to additive technology, and using recycled pet material in the printing process.